Implementation of coffee supplychain using ethereum smart contract addressing the issue of storing critical data necessary at different stages of supplychain and making it verifiable by all stakeholders in supplychain.

- This project showcases the journey of coffee beans on the

- The coffee supply chain is the sequence of activities and process to bring raw coffee beans from coffee farms to processed coffee in markets.

Problems in Existing System - Currently, Coffee trade mostly relies on fax machines and emails to send and receive contracts across the globe, resulting in slower and error-prone paperwork.

- Blockchain can solve this by providing immutable and verifiable data sources.

What We are Providing?

- We have implemented a smart contract addressing the issue of storing critical data necessary at different stages of supply chain and making it verifiable by all stakeholders in supply chain.

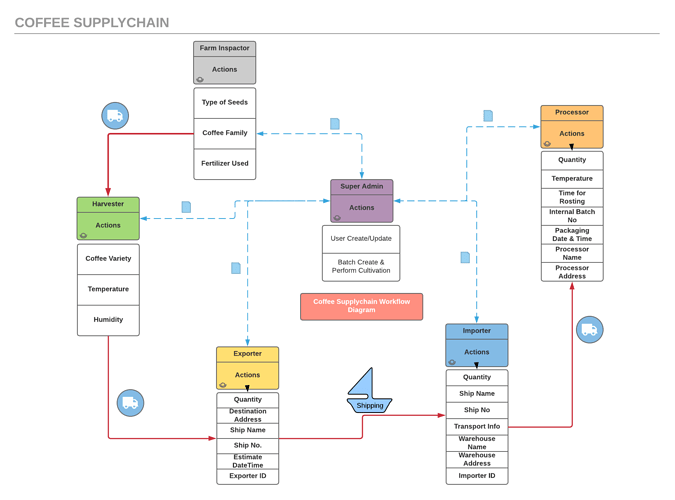

Application Workflow Diagram

In This Application, We Have Six Stages

- 1.Admin

- 2.Farm-Inspector

- 3.Harvester

- 4.Exporter

- 5.Importer

- 6.Processor

- Admin

Admin creates a new batch which is the initial stage of a coffee batch.

- Farm-Inspector

Farm-inspectors are responsible for inspecting coffee farms and updating the information like coffee family, type of seed and fertilizers used for growing coffee.

- Harvester

Harvesters conducting plucking, hulling, polishing, grading and sorting activities, further updating the information of crop variety, the temperature used and humidity maintained during the process.

- Exporter

Exporters are the organization who exports coffee beans throughout the world. Exporter adds quantity, destination address, ship name, ship number, estimated date, and time and exporter id.

- Importer

Importers imports the coffee from coffee suppliers and updates quantity, ship name, ship number, transporters information, warehouse name, warehouse address, and the importer’s address.

- Processor

Processors are the organizations who process raw coffee beans by roasting them on particular temperature and humidity and makes it ready for packaging and to sale into markets. The processor adds the information like quantity, temperature, roasting duration, internal batch number, packaging date time, processor name and processor address.

Demo user panel link : http://coffee-supplychain.rwaltzsoftware.com/